Degradation of vehicle performance is due to complex mechanical synchronization failures that require systematic diagnostic intervention. Advanced technical assessments reveal critical warning signs through precise monitoring of engine parametersincluding RPM fluctuations, abnormal combustion rhythms and unexpected acceleration inconsistencies. Professional technicians use data-driven methodologies, assessing the integrity of electronic sensors, ignition timing and spark plug performance to restore maximum engine functionality. Proactive maintenance protocolsincluding regular fluid analysis and component inspections, prevent catastrophic mechanical failures and extend operating life. The journey to mechanical restoration begins with understanding the intricate diagnostic landscape of your engine.

Contents

Many car owners find engine performance problems which can significantly impact driving efficiency and safety. Detecting problems requires an in-depth understanding of the engine's dynamics, particularly in relation to the ignition timing e engine RPM synchronization. Regular maintenance checks play a crucial role in preventing and identifying potential motor performance complications before they worsen.

Subtle indicators such as irregular acceleration patternsUnexpected RPM fluctuations and inconsistent power delivery signal potential motor disturbances. Diagnostic accuracy involves monitoring the integrity of the combustion cycle, examining the four-stroke sequence for possible timing disintegration. Consistent fluid maintenance supports optimum motor performance by ensuring adequate lubrication and reducing mechanical stress.

Professional technicians assess these performance anomalies through systematic evaluations of the fuel supply, spark plug functionality and calibration of the synchronization mechanism. Accurate identification of deviations in motor performance enables targeted interventions, preventing the mechanical deterioration and ensuring optimal vehicle operating standards.

Understanding these technical nuances empowers vehicle owners to proactively address emerging motoring complications before they turn into significant mechanical challenges.

Detect critical warning signs of motor performance requires systematic monitoring of the vehicle's operating parameters. Precise monitoring of ignition advance becomes paramount in identifying potential uncontrolled motor scenarios.

Engine vibrations serve as primary diagnostic indicators, signaling disturbances in mechanical synchronization that compromise vehicle performance.

The technical analysis reveals multiple symptoms: fluctuations of Inconsistent RPM, abnormal combustion rhythms and unexpected irregularities in power transmission. Experienced technicians recognize these manifestations as potential precursors of mechanical failures substantial.

Critical warning signs include sudden acceleration inconsistencies, unexplained increases in fuel consumption and persistent vibration anomalies in the engine compartment.

Methodical diagnostic approaches demand immediate attention when these symptoms emerge, preventing potential catastrophic mechanical collapse and ensuring optimal vehicle operational integrity.

Systematic fluid monitoring can reveal early indicators of potential mechanical problems, such as color-coded leaks that signal specific system problems that require professional attention. Comprehensive vehicle inspections can help identify potential performance problems before they develop into more significant mechanical problems.

While rigorous motor diagnoses require systematic precision, professional repair strategies encompass a multifaceted technical approach to uncontrolled motor interventions.

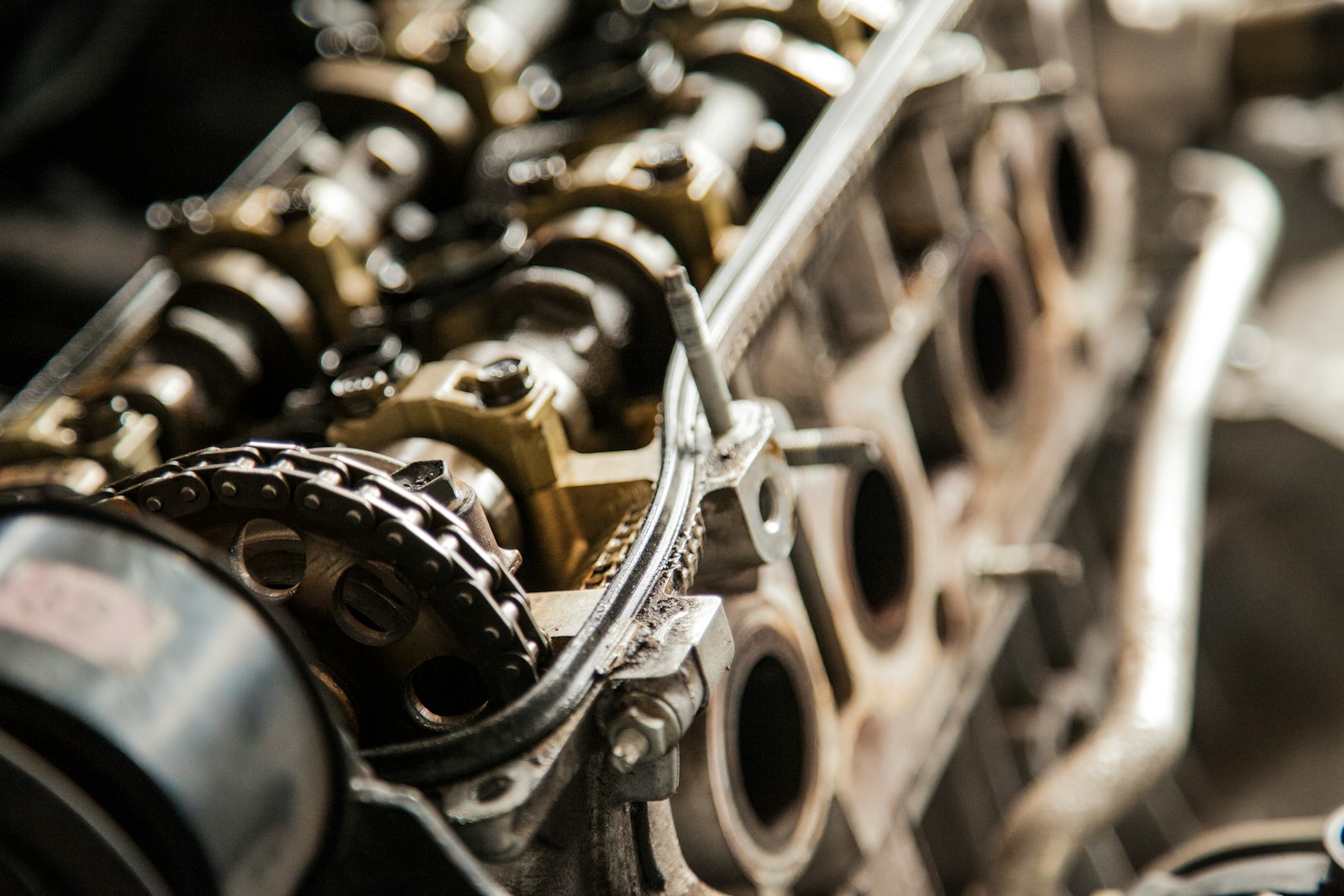

Expert mechanics use advanced diagnostic tools to assess ignition timing and analyze extensive engine timing parameters. Precision instruments such as oscilloscopes and specialized scanning equipment allow detailed analysis of irregularities in the combustion cycle, identifying specific timing disturbances.

Technicians methodically examine the performance of spark plugs, compression ratios and the integrity of electronic sensors to determine the root causes of engine deviations. Calibration techniques involve recalibrating ignition systems, adjusting timing mechanisms and checking the functionality of the electronic control module.

Extensive diagnostic protocols require a strategic, data-driven methodology that addresses mechanical and electronic components, ensuring optimal engine performance and restoring precise engine synchronization. Vehicle safety features play a critical role in diagnosing and assessing the performance of the motor system.

Vehicle classification directly influences motor performance parameters e regulatory compliance metrics. Precise categorization based on vehicle dimensions, weight and operational characteristics determines critical regulatory thresholds that impact operating costs and legal requirements.

Toll implications emerge distinctly among vehicle classifications, with heavier vehicles incurring substantially higher transit fees. Regulatory frameworks establish nuanced distinctions that determine technical inspections specific, emission standards and financial obligations for each vehicle category.

A strategic understanding of these classification systems allows owners to anticipate maintenance costspredict operational constraints and optimize vehicle management strategies.

Detailed assessment of vehicle regulations ensures effective navigation through complex transport infrastructure requirements, ultimately promoting safer and more economically efficient vehicle operations.

How critical are systematic maintenance protocols in extending automotive operating life? Precise maintenance techniques are the cornerstone of vehicle longevity, with oil change intervals e tire rotation serving as fundamental diagnostic interventions.

Systematic lubrication assessments prevent mechanical degradation, while strategic tire rotation mitigates uneven wear patterns that compromise vehicle stability and performance.

Systematic maintenance requires meticulous attention to the manufacturer's recommended service schedules, incorporating comprehensive diagnostic assessments of critical systems.

Proactive mechanical interventions-including extensive fluid analysis, component inspections and calibrated adjustments-optimize the mechanical integrity and anticipate potential systemic failures.

Weather conditions greatly impact engine timing performance by affecting multiple engine parameters.

Extreme temperatures, humidity and atmospheric pressure can disturb the ignition advancecompromising the engine's efficiency.

Cold environments increase the viscosity of the fuel and reduce battery performance, while intense heat can cause thermal expansionThis changes the dynamics of the combustion chamber and potentially disturbs the precise synchronization mechanisms in the engine's operating cycle.

Engine timing repair costs generally range from 200 to 1,500 euros, depending on repair cost factors such as the make of the vehicle, the complexity of the ignition system and the extent of the damage.

Professional diagnostic assessments are essential.

Engine maintenance tips include regular spark plug inspections, timely timing belt replacements, and addressing early warning signs to prevent extensive mechanical deterioration and minimize potential repair expenses.

Insurance cover for uncontrolled motor performance problems varies considerably between policies.

Standard car insurance usually excludes mechanical failures due to inadequate maintenance or gradual deterioration.

Specialized extended warranty or mechanical breakdown insurance can cover timing-related repairs, contingent on documented maintenance records and specific policy terms.

Evaluation accurate diagnosis determines the potential coverage.

Sensor technology revolutionizes motor synchronization management by monitoring performance in real time.

Algorithms for advanced predictive maintenance detect microscopic deviations in ignition timing before critical faults occur.

Integrated electronic control units with high-resolution sensors continuously analyze combustion parametersallowing proactive adjustments that maintain motor synchronization reducing performance degradation and minimizing potential mechanical disturbances.

"Where there's a will, there's a way" - electric vehicles are not entirely immune to the motor synchronization challenges.

Advanced motor control strategies inherently provide advantages to electric vehicles, using sophisticated electronic management systems that continuously monitor and adjust motor performance.

These precisely designed controllers dynamically regulate the electrical synchronizationThis reduces the traditional complications of synchronizing combustion engines through real-time algorithmic interventions.

Technical interventions converge strategically in optimizing motor performance, revealing systemic automobile synchronization methodologies. A diagnostic accuracy intersects with mechanical rehabilitation, generating extensive resolution architectures. Coincident engineering perceptions show that systematic maintenance protocols substantially mitigate mechanical instabilities. Advanced technological structures simultaneously address operational disturbances, establishing predictive performance paradigms. Lately, integrated diagnostic approaches transform potential mechanical vulnerabilities into engineered reliability infrastructures.